25.8Vehicle Interface

Even if you’re on the right track, you’ll get run over if you just sit thereWill Rogers, actor, 1879–1935

Having the platform level with the vehicle floor is one of the most important ways of reducing boarding and alighting times per passenger. Customers climbing even relatively minor steps can mean significant delay and an increase in safety hazards, particularly for the elderly, disabled, or people with walking aids, suitcases, or strollers. This is also true with horizontal and vertical gaps between the station and the bus. As mentioned previously, the BRT Standard includes level boarding as one of the BRT Basics, the essential elements of BRT. Having one of the highest points awarded to this indicates how important this element is to both operational efficiency and passenger experience.

Having the platform and vehicle at the same level speeds up alighting and boarding, and with it, reducing dwell time and improving overall performance.

- Level boarding is 0.2 to 0.7 seconds faster per passenger and alighting times 0.3 to 2.7 seconds faster per passenger compared to a buses where you have to go up steps.

- Stepping up or down to the vehicle renders the system unusable for persons in wheelchairs and problematic for others (using walking aids, persons carrying packages, children, etc.).

25.8.1Doors and Boarding Area

Sliding doors can provide a more professional impression and improve safety by deterring fare evasion through station doorways (Figure 11.60). Station doors can also help protect the customers from the weather – whether it be rain or hot or cold. If a station is heated or air conditioned, doors keep in the conditioned air. These doors may be controlled electronically from the vehicle or station, but should have a manual override, in case like in Figure 25.87 the door does not function. As mentioned above, this introduces a maintenance challenge and can lead to the doors not functioning and the system not having the capacity or resources to fix them.

Station doors need to be aligned with the vehicle types using the station, and within the station according to the space available on the BRT station structure. Where boarding and alighting takes place on both sides of the station, the doors should ideally be offset, so that waiting passengers in one direction do not impede boarding & alighting passengers in the other direction.

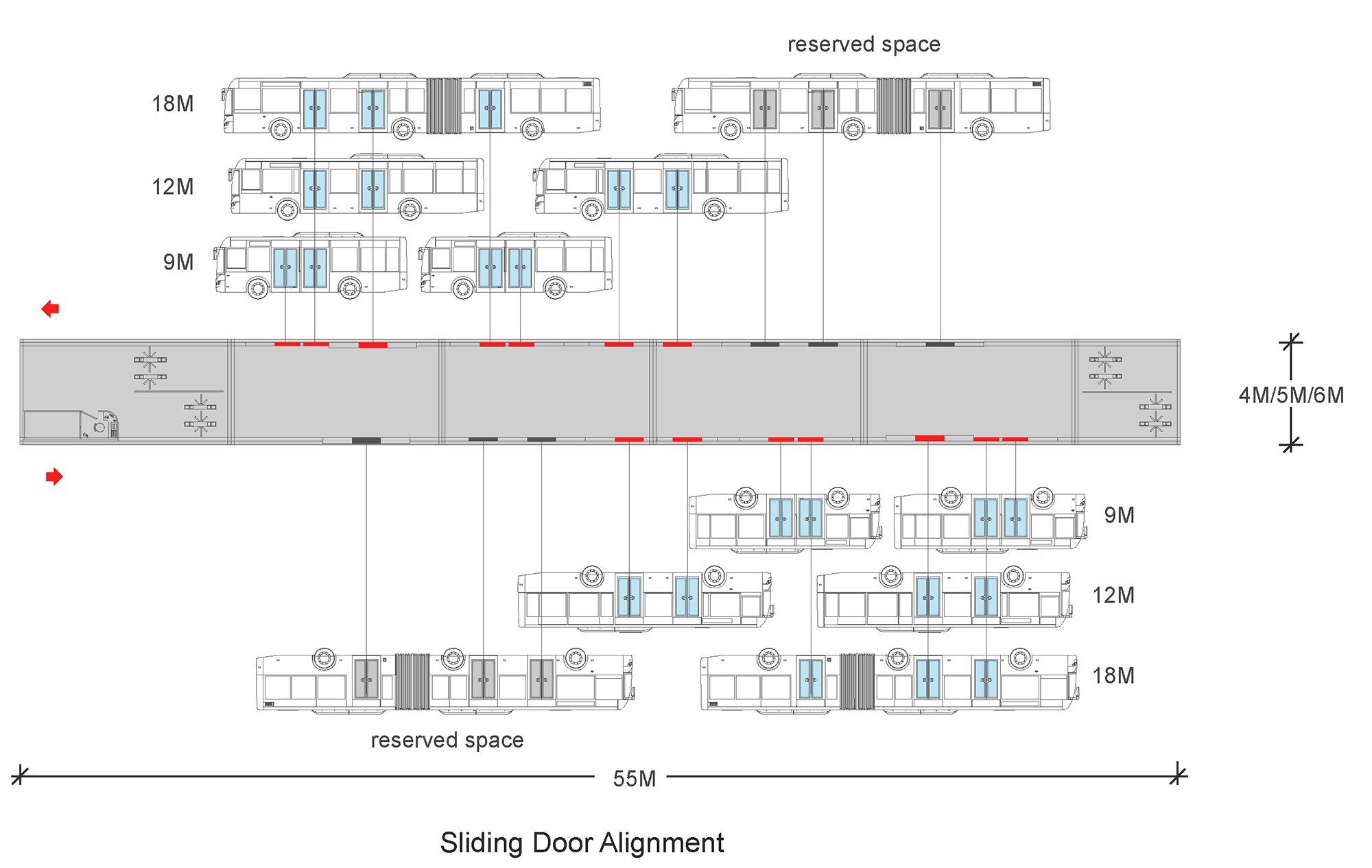

Figure 25.88 shows the proposed BRT station configuration in Vientiane. Note:

- The stations have been designed to accommodate a variety of vehicle types; namely 9-meter, 12-meter,

- and 18-meter BRT buses. In the short to medium term the 18-meter buses are not needed and are not recommended.

- The 18-meter BRT bus option is included only so that if needed capacity can be added in future.

- The doors of the vehicles align with the doors in the stations.

- The boarding and alighting areas for the two directions are offset, except for the middle set of doors. In the case of the middle doors, since this is the second docking bay and is not used at all for the initially proposed fleet of 9-meter buses, the likelihood of passengers in different directions impeding each other is low.

- Each direction has two docking bays for each direction.

- A ‘reserved’ space has been identified allowing the future installation of additional sliding doors, in case in the long term there is a need to use many 18-meter buses.

- The preferred station width is 5-meter or 6-meter, not 4-meter.

- A manned ticket selling booth is provided at one end of the station. The other end will have either exit-only functionality or provision only for smart-card entry.

25.8.2Platform-vehicle Alignment

The goal is to create a level boarding experience so that people using wheelchairs or walking aids, pushing strollers or carts, or jut carrying packages can easily and safely board and alight. To do that, the gap between the bus and station needs to be 10 centimeters or less, especially at the front of the bus where it is easier to bring the bus closer to the station. Below are some of the more common ways systems have used to minimize the gap:

- Boarding bridges: These are mechanical bridges that extend from either the bus or the station (such as in Yichang) to cover the gap between the bus and the station;

- Alignment Markers: Most BRT systems use alignment markers on the busway surface, in combination with markers on the vehicle windscreen, to assist drivers to dock with a minimal vehicle-to-platform gap. Some BRT systems also utilize a painted “guide strip” that lines up with a guide line on the bus’s windshield that aids drivers in docking the bus closely to the station;

- Platform Edge Treatment: It is a common practice to provide a protective edge on the platform, typically matched by a protective strip opposite the platform edge that runs along the length of the vehicle; and

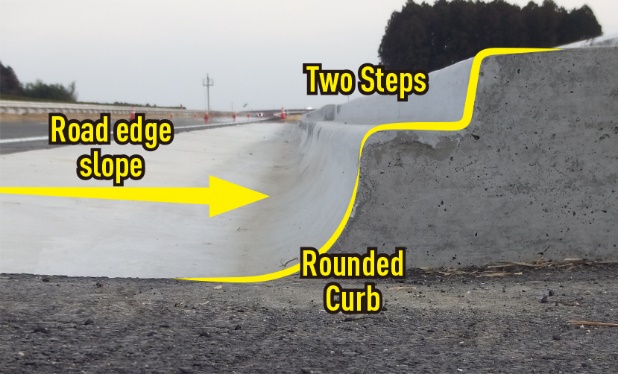

- Beveled Curbs: The BRT in Nantes uses beveled curbs to assist vehicles in docking near the edge of the platform. The curb is hardened and smoothed to reduce wear on vehicle tires. The Cape Town BRT uses special curbs to assure that the vehicles can dock near the platform without risk of damage to the vehicle. This increases confidence in drivers that they may safely reduce the gap for boarding passengers. The Kassel curb allows the wheel of the vehicle to make contact with the curb so the driver can “feel” where to position the vehicle correctly through the steering system. It helps the driver and vehicle align with the curb for seamless boarding and alighting. See Figure xxxx.

If the vehicle to platform interface does not utilise a boarding bridge, then greater precision is required to align the vehicle to the platform. While a boarding bridge only requires a vehicle to be within 40 centimetres of the platform, the lack of a boarding bridge requires that the vehicle be aligned within 10 centimetres or less, if the station is to be wheelchair accessible, especially at the front of the bus where it is easier to closer to the platform. This degree of precision will require a longer approach distance in order to maintain an effective speed. Ahmedabad has door sensors and the door cannot be opened if the gap exceeds an allowable width. The driver then has to re-align the vehicle.

To ensure close docking without the use of boarding bridges, a combination of the following are needed:

- Driver training, as well as monitoring of driver performance in this regard;

- Adequate approach distances, especially where stations have passing lanes;

- Kassel curbs or sloping curbs that enable buses to stop close to the platform without actually striking the platform; and

- Especially for high floor systems where closer docking is more critical, some form of padding is often utilized (see Figure 25.89).

- Visual aids to drivers so they know exactly where to stop the bus (Figure 25.90).

Box 25.4 Solutions to Minimizing the Gap: A case study

Using a beveled curb allows drivers to pull up close to the station by using the curb to guide the bus. This means added wear and tear to the tires as they rub against typically the concrete curb surface, even if those curbs are bevelled or smoothed. To compensate for this that results in excessive tire side wall wear, many tires are reinforced with thicker rubber, which increases the weight of the tires by a third more. This added weight means more fuel consumption.

In an effort to address this, Bridgestone has been experimenting with both the curb and the tire to reduce the wear and tear of the tire, as well as its weight, while helping getting a closer alignment. It is a mix of redesigning the idea of a beveled curb to better work with buses and drivers to get closer to the station, while redesigning the tire for that type of approach.

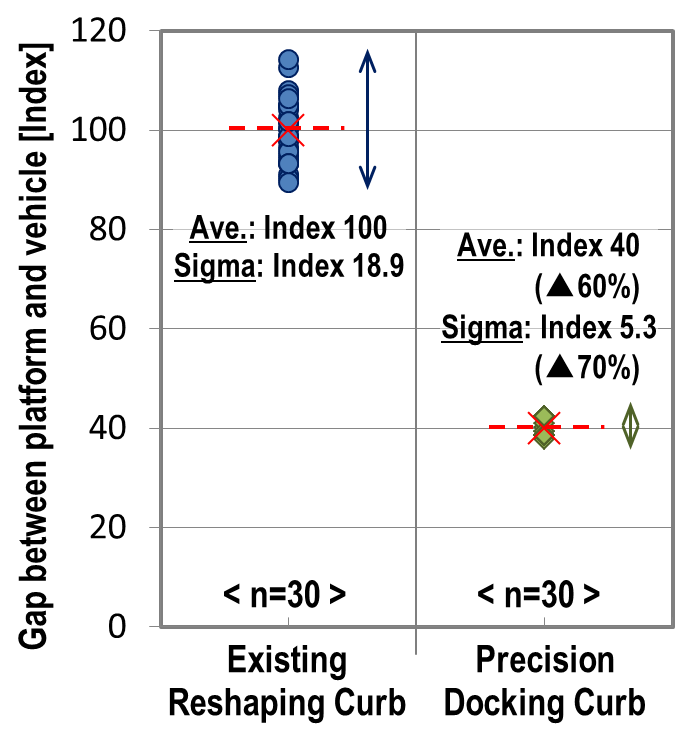

In what they are calling the “Precision Docking Curb,” Bridgestone builds on the idea of the beveled curb with two additional features which help buses align to the station better. The first is the gently slope the roadway toward to the station curb, which enables buses to naturally approach curbs with minimal steering. This serves as a means of controlling the angle of approach to the curb without rely on to the driver’s skills. The second big change this introduces is to step back the curb to avoid the curb hitting the body of the buses when approaching the station. In a study testing the performance between existing beveled curbs and the precision docking curb, the precision docking curb performed significantly better with less variation (see Figure 25.97) To address the wear and tear to the tire, Bridgestone has developed the tire reside technology. This allows the tire casing to be replaced, but the internal tube can be reused over and over again. This technology also slows down the speed with which the tire sides wear, meaning these tires last 25 percent longer than a conventional tire.

These both improve the platform-vehicle interface with narrower gap and less variances, which significantly affect accessibility for a variety of users.

Various electronic systems are used to ensure proper platform-vehicle alignment, though these are much more expensive than visual alignment markers guiding the drivers at a fairly marginal additional benefit, especially in cases where capacity issues mean that rapid docking is more important to overall system performance than precision docking.

- Optical Guidance - a video camera detects the position of the bus relative to the station and helps guide the vehicle. Optical guidance systems are used in Rouen, France, Castellón, Spain, and Bologna, Italy; and

- Magnetic Alignment - a path is laid magnetically using a loop, wire, or permanent magnetic studs that are read by sensors underneath the bus to guide the vehicle. Magnetic alignment technology is employed in Eindhoven, The Netherlands.