20.3Vehicle Floor Height

A lot of people are afraid of heights. Not me. I’m afraid of widths.Stephen Wright, comedian, actor, writer, and producer, 1955–

After the physical length, the floor height tends to be one of the most crucial physical characteristics of the vehicle. The floor height will affect decisions on boarding and alighting strategies, customer convenience, vehicle costs, and maintenance costs.

In general, there are a full range of options including low floor, semi-low floor, and high-floor vehicles. With any of these options, a level (step-free) boarding is possible. Most of the well-known Latin American systems, such as Bogotá and Pereira, Colombia, Curitiba and Goiânia, Brazil, and Guayaquil and Quito, Ecuador operate high-floor vehicles with platform-level boarding.

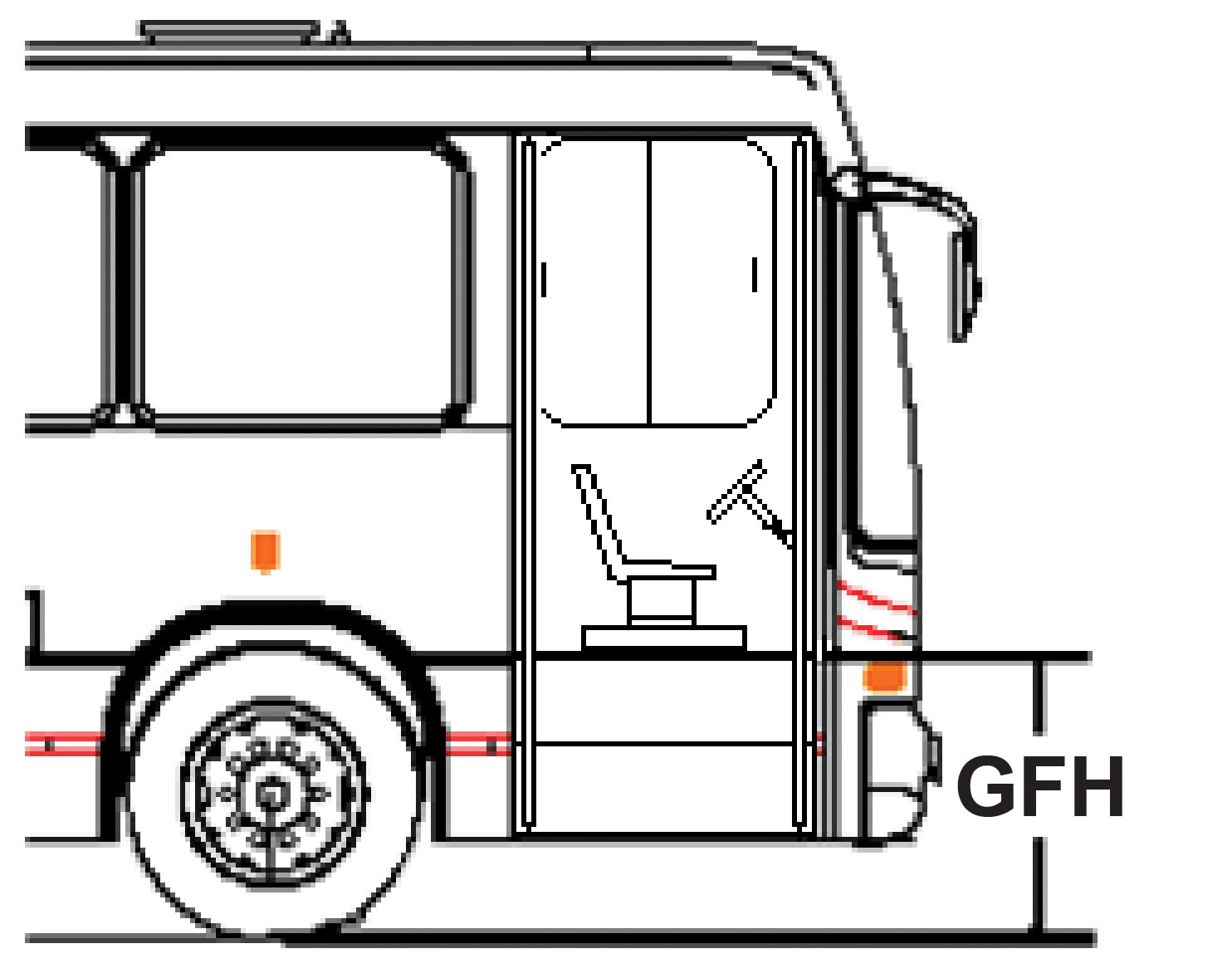

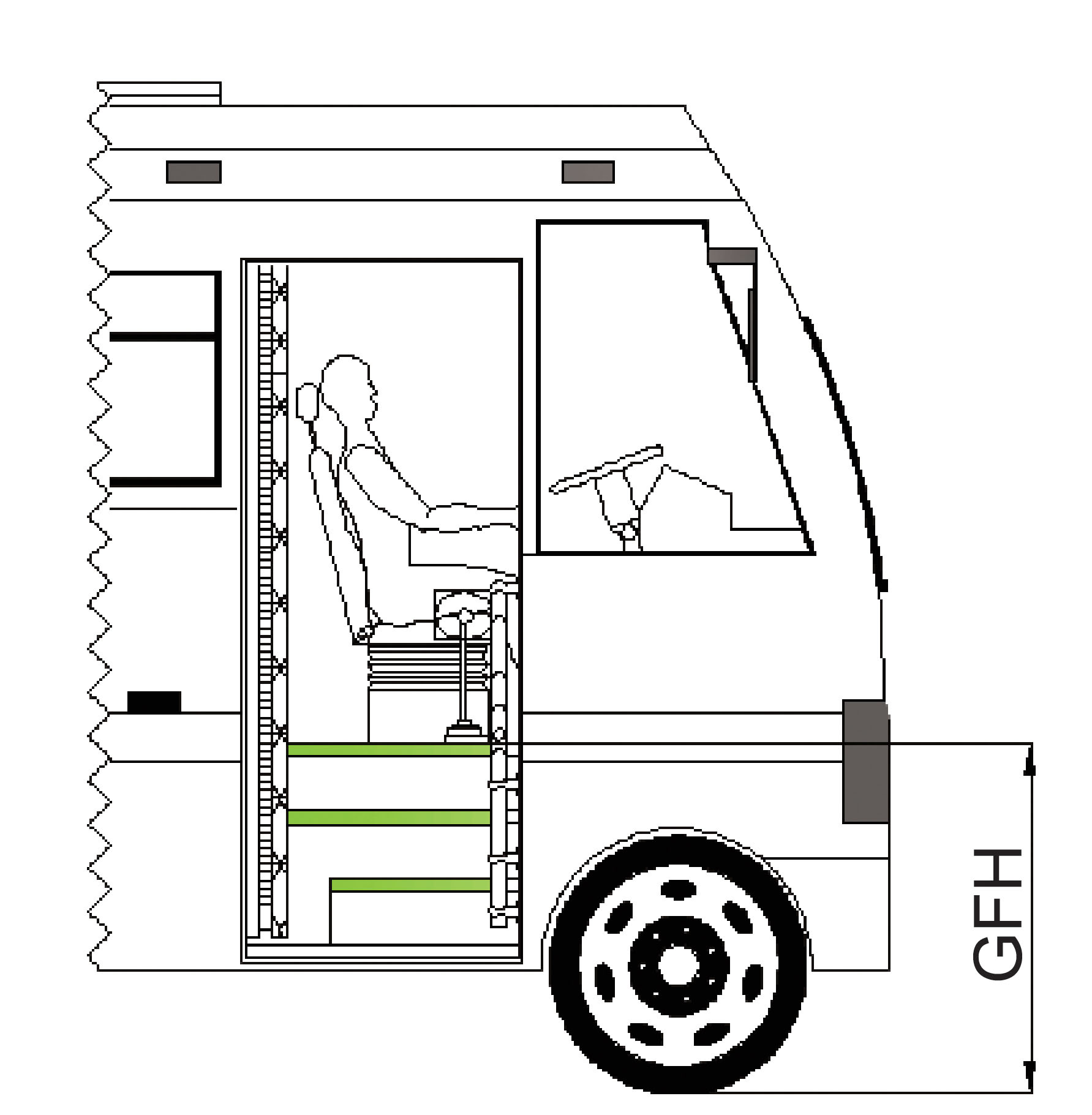

Vehicle chassis tend to be produced in certain standard floor heights. Two of the most common interior floor heights are 38 to 40 centimeters (low-floor) and 90 centimeters (high-floor). There are also low-floor models with an interior floor height of less than 38 to 40 centimeters.

20.3.1Low-floor Versus High-floor Vehicles

From the perspective of BRT systems, the debate over low-floor versus high-floor is somewhat secondary to the preference for platform-level boarding and alighting. Steps of any type will slow dwell times, as well as make a system off-limits to many of the physically disabled. Even low-floor vehicles, if not at level but still requiring a small step up or down, can slow boarding times, as well as create a usage barrier to persons in wheelchairs.

Fig. 20.7, 20.8, and 20.9 The distance from the ground to the vehicle floor differs depending on vehicle length and engine location.

Attempting to operate stepped boarding and alighting in high-volume operations can be detrimental to system performance, regardless of floor height. Both low-floor and high-floor vehicles can be adapted for usage with platform-level boarding. The Transantiago system in Santiago, Chile, elected to operate low-floor (20-centimeter) vehicles without platform-level boarding. In conjunction with the decision to have on-board fare verification, the result has been serious station delays (Figure 20.10). Likewise, the Brisbane, Australia, system also combines low-floor vehicles and on-board fare verification (Figure 20.11). While these types of systems may provide an adequate service, they cannot match the operational performance levels of cities utilizing platform-level boarding.

Low-floor vehicles have predominantly been deployed in conventional bus systems in developed nations in Europe and North America. These systems generally operate without closed stations, platform-level boarding, or pre-board fare verification. In such cases, low-floor vehicles provide a somewhat better physical image and make boarding easier in comparison to high-step entry.

As low-floor bus technology becomes more affordable and widely available in developing countries, it has become a matter of debate whether new BRT systems should be designed for use with high- or low-floor vehicles, and whether the high BRT platform is necessary or desirable.

The principal advantages of low-floor vehicles relate to the physical image of the vehicles, as well as some aspects of operational flexibility. The principal advantages of high-floor vehicles relate to the procurement and maintenance costs of the vehicles Further, high-floor vehicles in conjunction with platform-level boarding actually offer smaller dwell times and greater access for the physically disabled than low-floor vehicles without platform-level boarding.

Low-floor vehicles offer greater operational flexibility since the vehicles can operate with and without boarding platforms. For BRT systems where the vehicles are likely to operate both on trunk corridors and in direct service, where no boarding platforms will be available, the low floor height helps increase customer boarding and alighting speeds during the curbside boarding sections of the route

In instances where the trunk vehicle operates with two-sided doorways, the low-floor design can ease customer movements within the vehicle. If a vehicle operates with high-floor on one-side (median station) and low-floor on the other (curbside station), then there will be steps inside the vehicle. This configuration is utilized in Porto Alegre, Brazil.

Low-floor vehicles can also be preferred for aesthetic and urban design reasons. The 50-centimeter difference in vehicle floor height means that the station height is reduced by 50 centimeters. This height reduction can help to mitigate concerns over roadway severance.

However, low-floor buses have their drawbacks. Being closer to the ground, the buses typically incur more structural stress and thus have higher maintenance costs. Road surfaces must be maintained at a very high level for low-floor bus routes in order to avoid and minimize any potential vehicle damage. These problems will be made worse if flooding is a risk along the BRT corridor. Small imperfections in the road surface will also tend to make the ride less smooth and comfortable for the users.

Low-floor vehicles have somewhat lower customer capacity in comparison with high-floor vehicles, because the wheel wells encroach on the customer-seating area. Low-floor vehicles also always have stairs inside them, as the rear vehicle seats are elevated above the wheels. This constrains customer circulation and limits access for all. Standard tow trucks are not always able to move low-floor vehicles when there are mechanical problems, so specialized towing vehicles are required.

Low-floor vehicles also somewhat complicate preventing fare evasion. With a ramped-entry high-floor vehicle, the height of the platform acts as a natural barrier against individuals trying to enter from outside the station. With low-floor vehicles, fare evaders can sneak between the station and the vehicle, and then enter the vehicle with relatively little difficulty. A way to avoid this is to install platform screen doors.

Low-floor vehicles also typically cost 20 to 30 percent more than standard models, and in some cases, upwards of 100 percent more (as is the case in India). Manufacturing low-floor vehicles requires the use of modern manufacturing technology, which is not always available in developing countries. In some cases, this means that the use of a low-floor vehicle will affect whether the vehicles can be assembled locally or will need to be imported, and thus have a significant impact on the cost of both procurement and maintenance. Table 20.3 summarizes the various trade-offs between high-floor and low-floor vehicles.

Table 20.3Comparison between high-floor and low-floor vehicles.

| Factor | High-floor Vehicle | Low-floor Vehicle |

|---|---|---|

| Purchase cost | Lower purchase costs | More complex chassis results in a purchase cost approximately 20 to 100% higher than high-floor vehicles |

| Maintenance cost | Distance from roadway impacts reduces maintenance costs | Higher maintenance costs (10%to 20%) due to proximity to roadway imperfections |

| Urban design aesthetics | Station profile will be 50 centimeters higher | Station profile will be 50 centimeters lower and thus will somewhat reduce visual severance |

| Customer convenience | High-floor vehicles with platform-level boarding eases boarding and alighting and has better circulation for all | If at-level boarding, then access for all, but internal circulation compromised by stairs. Often, low-floor stations are not at-level, but still require a step up, making wheelchair entry difficult |

| Vehicle towing | In case of breakdown, high-floor vehicles can be towed by a conventional tow truck | Many low-floor vehicles require a special type of towing vehicle |

| Fare evasion | Provides a better natural defense against fare evasion | More susceptible to fare evasion |

| Vibrations | Higher suspension somewhat reduces roadway bumps and vibrations | Somewhat more susceptible to roadway vibrations and thus making reading potentially more difficult |

| Seating | Little to no impact on seating arrangement from the wheel-wells | Some impact on the height and number of seats due to the wheel-well |